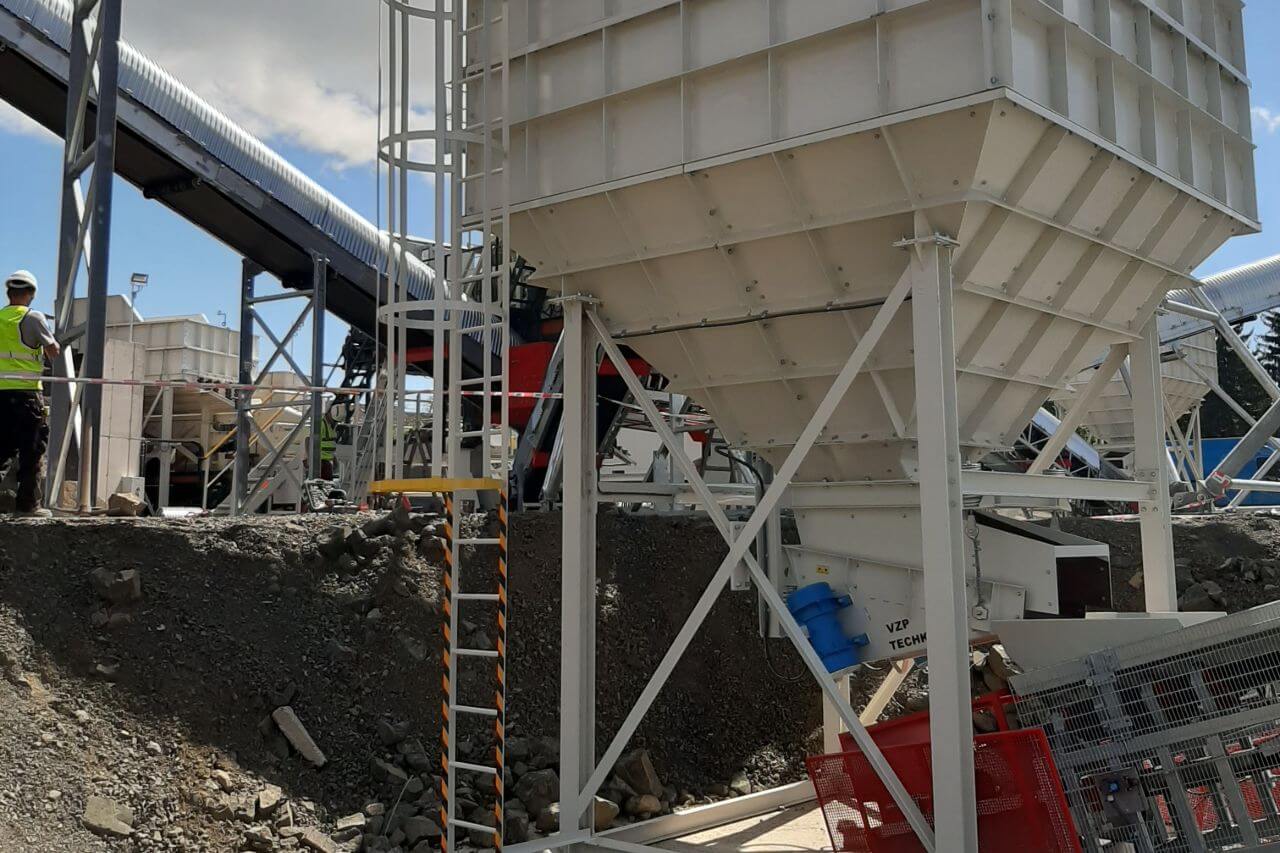

Covering of conveyers

Covers are made of both-side galvanised steel corrugated plates (profile 18/76) – for all ordinary belt conveyors.

Covers are:

- self-supporting (steel plate 0,6 mm)

- fire proof and thermostable

- fire proof and thermostable

- do not need any maintenance for many years

- easy to use

- without complicated supporting structure

- ekological

- attractively priced

For the purpose of the conveyor control the covers can be easily removed and set back. It is possible to order covers with closing inspection vent, also full-open concepted, or with permanent control vents.

| Covers # | Belt width (a) | Construction width (b) | Radius(r) | Direct segment (g) |

| 1 | 400 | 700 | 350 | minimum height 200 – 500 ask for higher |

| 2 | 500 | 800 | 400 | |

| 3 | 650 | 950 | 475 | |

| 4 | 800 | 1150 | 575 | |

| 5 | 1000 | 1350 | 675 | |

| 6 | 1200 | 1600 | 800 | |

| 7 | 1400 | 1800 | 900 |

You can ask for other dimensions. All dimensions in mm.

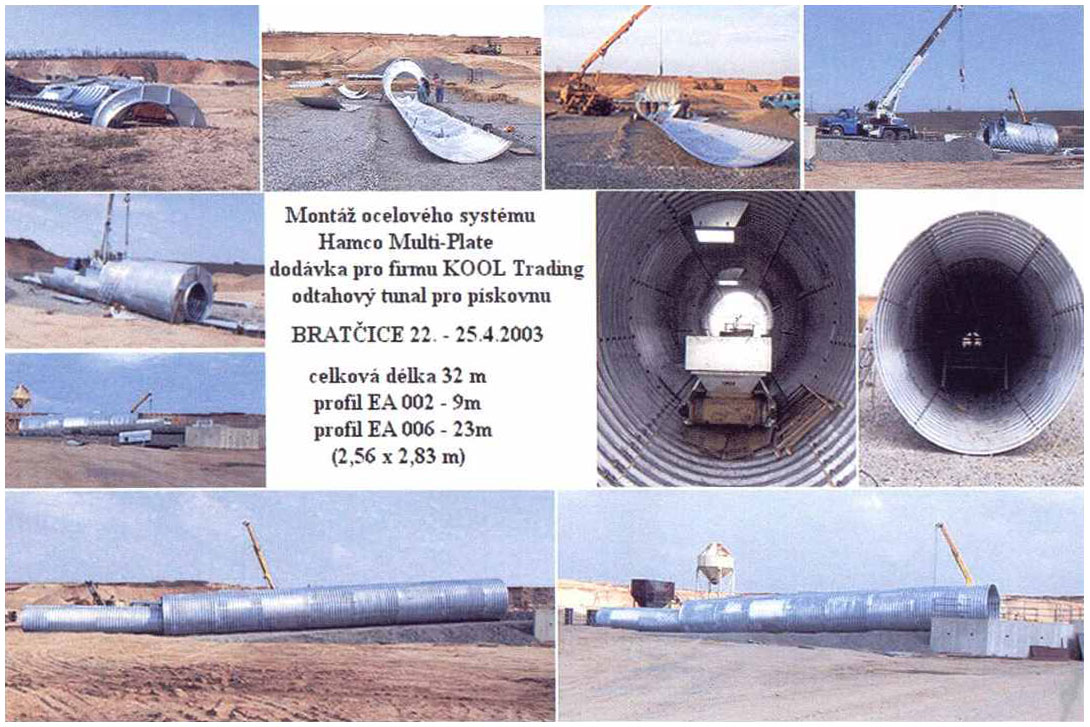

Tunnels

In this domain our company only provides sale and assembly of tunels and silos of HAMCO company.

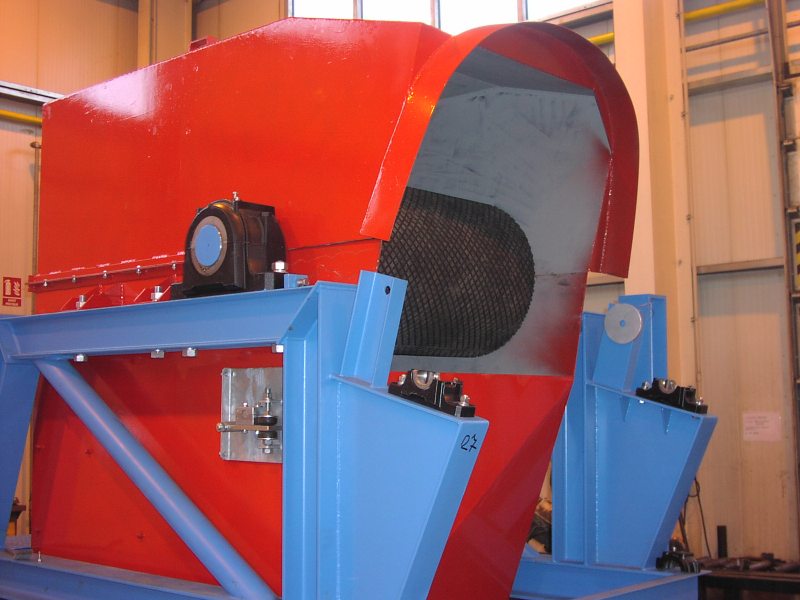

Rubber anti-abrasive coating

Are formed of two basic materials – steel clops, serving as a supporting and fixing element, and vulcanised rubber layer of hardness 60 Sh. They are used for reduction of consumption of metals and labour, noise reduction and labour safety arising. They are mounted into transfer point equipment, chutes, hoppers and storage bins where crushed stones drop, or other bulk materials so to direct the impact of the dropping material perpendicularly to the reflecting plane. It cannot be recommended to use it with extremely hard materials (whinstone, etc.).

Possibilities of use:

- Type 1 – for coating reflective surfaces up to the grain size of gravel 32 mm (transfer points, bottoms of storage bins, reflective bars, etc.)

- Type 2 – for coating reflective surfaces up to the grain size of gravel 63 mm (transfer points, storage bin bottoms, reflective bars, etc.)

- Type 3 – for coating reflective surfaces at grain size of gravel over 63 mm (hoppers of primary crushed raw material, chutes, etc.)

| Type | Thickness (mm) | Weight (kg) |

| 1 | 40 | 5,25 |

| 2 | 70 | 3,960 |

| 3 | 100 | 5,285 |

The client himself supplies the nuts and washers.